WOOD CHIP AND PELLET BOILER

350 – 550 kW

- Sturdy construction

- Industrial model

Wood chip and pellet boiler

NEW! TMe

Froling’s Turbomat is a unique heating system with a fully automatic wood burner which will operate with a wide variety of wooden material. As a leading manufacturer of biomass heating systems, the Turbomat embodies all of Froling’s expertise in pioneering innovation. We were looking for a boiler that would be perfectly suited for burning other biomass fuels as well as wood chips.

The Turbomat not only boasts innovative combustion technology but also offers impressive control options. With Lambda controls as standard, combustion chamber temperature monitoring and under-pressure control, perfect combustion is guaranteed for a range of materials. The comfort provided sets new standards in this performance category.

From material feed to combustion, to cleaning and ash removal, everything is fully automated. Despite all its high-tech features, the Turbomat is designed for exceptionally easy maintenance.

Information/advice

You would like to have further product information or you have general questions regarding our company?

The latest technology

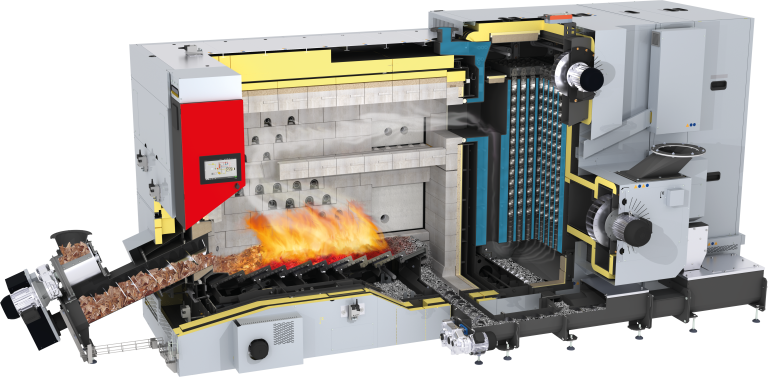

Air intake through the thermally insulated outer shell for combustion air preheating (= adiabatic combustion chamber)

High temperature combustion zone

This increases efficiency even further, particularly with poor quality fuels.

Vertical 3-pass heat exchanger with integrated efficiency optimisation system (WOS) with automatic cleaning function. Operating pressure 6 bar (8 bar on request).

High-temperature flue gas recirculation

FGR

Optimises the results of the combustion process (output, emissions, etc.) for particularly demanding fuels such as pellets, shavings, etc.

Combined electrostatic precipitator - EFZ multicyclone unit

Combination of electric filter and multicyclone separator for guaranteed very low emission values.

Speed-controlled and monitored induced draught fan, Optionally integrated at three positions directly on the boiler. Can also be installed flexibly at an external position.

Bypass flap for optimised partial load operation and flue gas temperature control.

Collective ash removal from the combustion

chamber and fly ash

Self-contained or for connection to further centralised ash removal system.

Generously dimensioned grate ash screw

Large combustion chamber doors on both sides

Actuated moving grate

Split primary air zone

Automatic ignition

Optional second ignition fan can be fitted for fuels of materials that are difficult to light (due for instance to high water content).

High-temperature combustion chamber with 4-layer jacket, for optimum combustion even with low-quality fuel (e.g. high water content, ...) or alternative fuels. Internal structure: innovative module components made of high-temperature-resistant silicon carbide / first thermal insulation / air jacket / second thermal insulation.

Stoker kit with large-volume,

2-chamber rotary valve with low

installation height

Air-cooled slide-on duct which guarantees minimal energy consumption in the fuel feed-in area and full flexibility for variations in the size of pieces of fuel. The drive gearbox unit to industrial standards is durable, which results in useful pre-drying of the heating material, particularly for fuels with a higher moisture content.

Industrial PLC with 10,1“ glass touch display for easy and intuitive operation

PLC control cabinet

Mounted on the boiler and pre-wired to the electrical components installed on the boiler.

Systematic convenience

The PLC 4000 controller is built using high-quality industry-standard components. The clear, user-friendly control system offers a wide range of different settings and visualisation options for individual, efficient and stable operation. The Froling PLC 4000 offers numerous functional options such as multi-sensor storage tank management, heating circuit and network temperature control, external output specifications, cascade function, integration, monitoring and control of additional peripheral components.

Advantages

Powerful controller with big colour touch display

Safe and simple remote access via Froling visualisation software

Numerous functional possibilities

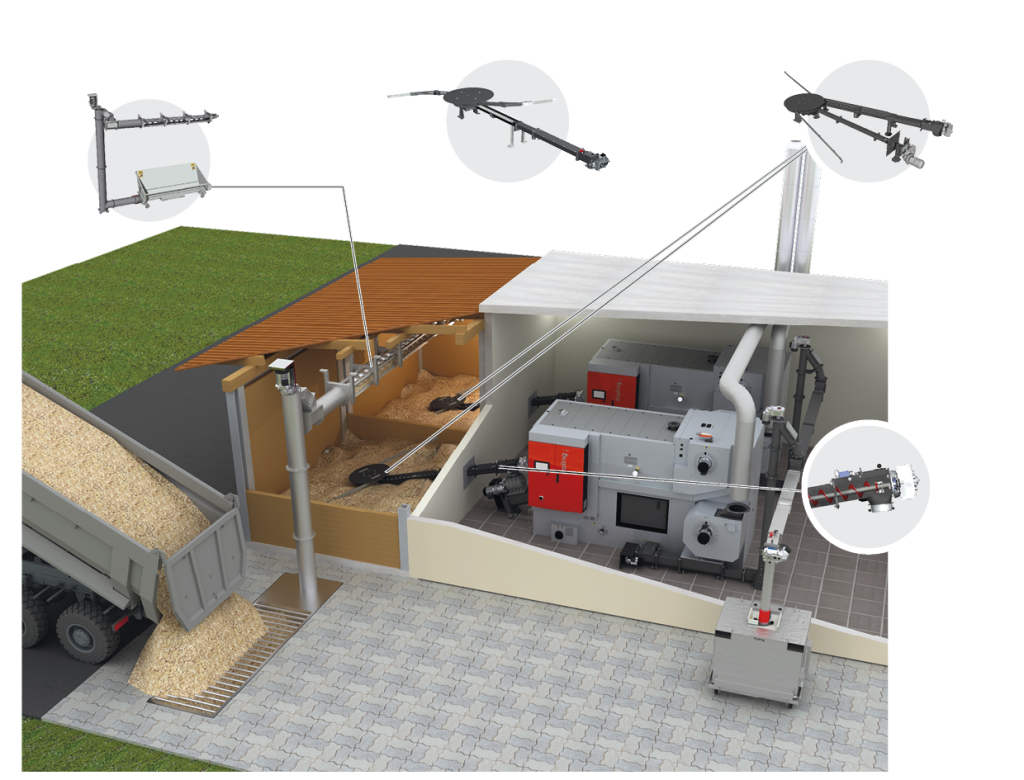

BFSV-H vertical feed screw bunker filling system

FBR-G with separate rotary agitator

FBR-G with separate rotary agitator

GAR-G system with separate rotary agitator

Progressive metering screw with modular plug-in system

The progressive feed screw guarantees reliable fuel transport. Thanks to the progressive screw pitch, the material does not become compacted and can always be transported easily. This ensures less force and energy consumption. The modular design of the feed screw with standard extension pieces between 100 and 2,000 mm (increments of 100/200 mm) allows easy assembly and flexible positioning of the system in the boiler room. The Froling feed screw does not require sloping sides.

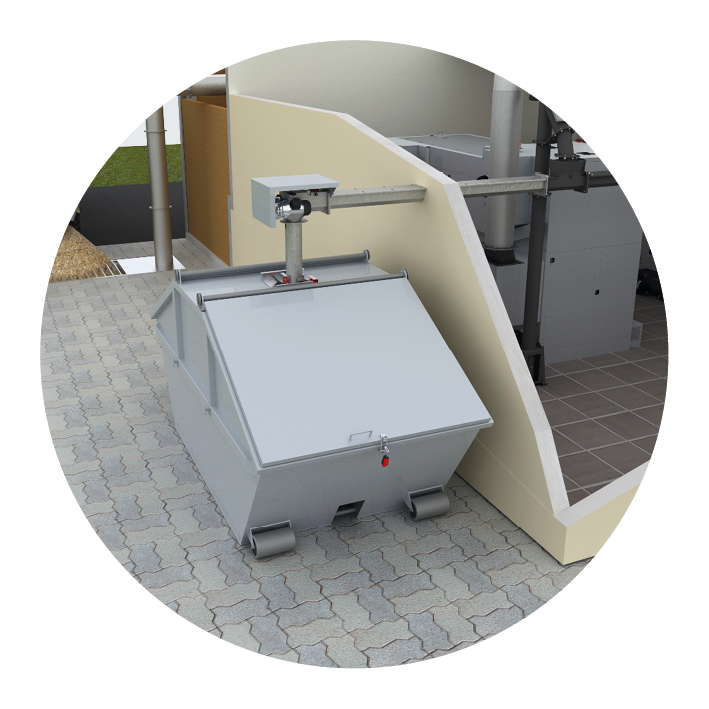

Flap-bottomed container (galvanised for exterior installation)

The ash is automatically conveyed into the flap-bottomed container whence it can easily be emptied. This ensures long emptying intervals and maximum convenience. Available in sizes 330, 500 or 1000 ltr.

Ash removal

- Vertical ash removal system

- Central ash removal

Froling will plan an individual central ash removal system to the customer’s requirements. Collecting screws are employed to gather the ash from various points (such as the heat exchanger, grate, etc.) and convey it to a central external point. Standard ash container (240 ltr, 1100 ltr), flap-bottomed container (500, 1000 ltr) or ash pit (7000 ltr, 10,000 ltr, …).

Suitable for coarse wood chips P63 (previously G100)

Depending on the application, raking chain conveyors, conveyor belts or hydraulic cross feeders may be used, with the option of connection of sprinklers.

Fröling storage tank systems with sensor strip

Fröling storage tank systems are available in various sizes and are also ideal for combining with other energy systems.

Hydraulic loading

The burn back slide valve closes off the fuel feed-in from the fuel store compartment. The fuel is fed into the combustion chamber directly on to the moving grate by means of a hydraulic ram. Available from TMe 350 kW. For coarse fuels up to P63 (formerly G 100).

EFZ 350-550 kW electrostatic precipitator cyclone

The modular electrostatic precipitator system combines the function of electrostatic charging of dust particles and the centrifugal separation of a multicyclone to reduce fine dust emissions.

Sliding floor discharge unit

The sliding floor discharge unit is used to discharge combustion materials from a rectangular or square bunker. The sliding floor discharge system can be equipped with one or more slide rods and is installed on the flat floor of the bunker.

Hydraulic loading

The burn back slide valve closes off the fuel feed-in from the fuel store compartment. The fuel is fed into the combustion chamber directly on to the moving grate by means of a hydraulic ram. Available from TMe 350 kW. For coarse fuels up to P63 (formerly G 100).

Modular components made of silicon carbide

Innovative modular components made of high-temperature-resistant silicon carbide for optimal combustion.

Brochures / EU Label

Technical specifications

| Technical specifications - TMe | 350 | 400 | 450 | 500 | 550 |

|---|---|---|---|---|---|

| Rated heat output [kW] | 349 | 399 | 449 | 499 | 549 |

| Output range [kW] | 104,7 – 349 | 119,7 – 399 | 134,7 – 449 | 149,7 – 499 | 165 – 549 |

| Rated thermal input of fuel with wood chips [kW] | 366,2 | 418,2 | 470 | 535 | 589 |

| Nominal thermal input of fuel [kW] with pellets | 361,3 | 413 | 465 | 521 | - |

| Required fuel quantity at nominal load for NL wood [kg/h] chips / pellets | 101 / 71 | 116 / 81 | 131 / 95 | 145 / 102 | 160 / - |

| Electrical connection | 400V / 50Hz / C35A or as shown on the circuit diagram | 400V / 50Hz / C35A or as shown on the circuit diagram | 400V / 50Hz / C35A or as shown on the circuit diagram | 400V / 50Hz / C35A or as shown on the circuit diagram | 400V / 50Hz / C35A or as shown on the circuit diagram |

| Max. permissible operating pressure [bar] | 6 (8¹) | 6 (8¹) | 6 (8¹) | 6 (8¹) | 6 (8¹) |

| Total dry weight including attachments [kg] | 7475 | 7475 | 7475 | 7475 | 7475 |

| Weight - combustion chamber incl. SiC modules [kg] | 4316 | 4316 | 4316 | 4316 | 4316 |

| Weight of SiC modules [kg] | 2063 | 2063 | 2063 | 2063 | 2063 |

| Weight - heat exchanger [kg] | 1858 | 1858 | 1858 | 1858 | 1858 |

| Combustion chamber installation dimensions (L x W x H) incl. collision protection and insulating sheet panelling [mm] | 2779 x 1461 x 2278 | 2779 x 1461 x 2278 | 2779 x 1461 x 2278 | 2779 x 1461 x 2278 | 2779 x 1461 x 2278 |

| Dimensions required for heat exchanger [mm] installation (L x W x H) | 1560 x 1345 x 2301 | 1560 x 1345 x 2301 | 1560 x 1345 x 2301 | 1560 x 1345 x 2301 | 1560 x 1345 x 2301 |

| Flue spigot diameter [mm] | 300 | 300 | 300 | 300 | 300 |

| Heat exchanger water capacity [ltr] | 1040 | 1040 | 1040 | 1040 | 1040 |

| Minimum boiler return temperature [°C] | 65 | 65 | 65 | 65 | 65 |

| Max. permitted operating temperature [°C] | >100² | >100² | >100² | >100² | >100² |

| Flue gas temperature (at nominal load / at partial load) [°C] | 140 / 110 | 140 / 110 | 140 / 110 | 140 / 110 | 140 / 110 |

| Permitted fuel as per EN ISO 17225 | Part 4: Wood chips P16s - P45s class A1 + A2 P63 with hydraulic loading, Part 2: Wood pellets, D06 / class A1 + A2 | Part 4: Wood chips P16s - P45s class A1 + A2 P63 with hydraulic loading, Part 2: Wood pellets, D06 / class A1 + A2 | Part 4: Wood chips P16s - P45s class A1 + A2 P63 with hydraulic loading, Part 2: Wood pellets, D06 / class A1 + A2 | Part 4: Wood chips P16s - P45s class A1 + A2 P63 with hydraulic loading, Part 2: Wood pellets, D06 / class A1 + A2 | Part 4: Wood chips P16s - P45s class A1 + A2 P63 with hydraulic loading, Part 2: Wood pellets, D06 / class A1 + A2 |

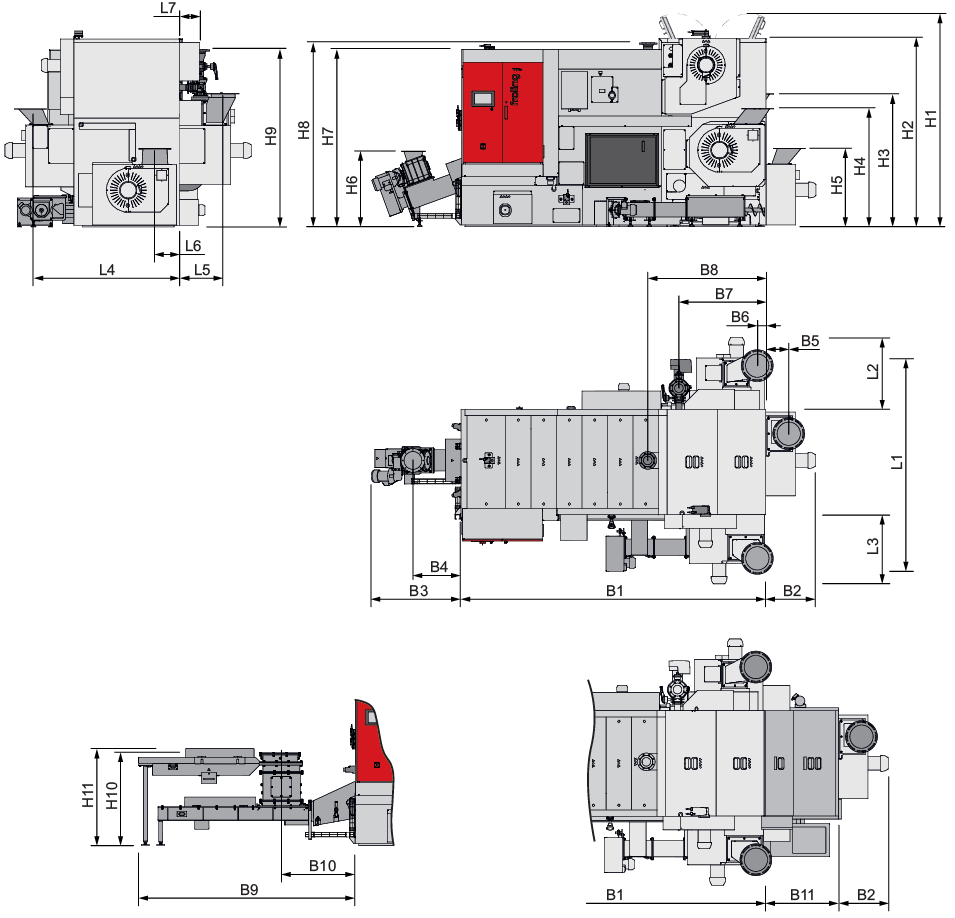

Dimensions

| All dimensions in mm - TMe | 350 | 400 | 450 | 500 | 550 |

|---|---|---|---|---|---|

| L1 Overall length incl. collective ash removal and return temperature control | 2670 | 2670 | 2670 | 2670 | 2670 |

| L2 Length of induced draught fan (opposite control cabinet) | 890 | 890 | 890 | 890 | 890 |

| L3 Length of induced draught fan (control cabinet side) | 865 | 865 | 865 | 865 | 865 |

| L4 Distance between flue gas pipe connection (control cabinet side) and side of boiler | 1860 | 1860 | 1860 | 1860 | 1860 |

| L5 Distance between flue gas pipe connection (opposite to the control cabinet) to boiler side | 550 | 550 | 550 | 550 | 550 |

| L6 Distance between flue gas pipe connection (opposite the stoker) and side of boiler | 300 | 300 | 300 | 300 | 300 |

| L7 Distance between return connection and back of boiler | 265 | 265 | 265 | 265 | 265 |

| B1 Total width | 3815 | 3815 | 3815 | 3815 | 3815 |

| B2 Width of induced draught fan (opposite stoker) | 625 | 625 | 625 | 625 | 625 |

| B3 Width of stoker (screw-fed) | 1120 | 1120 | 1120 | 1120 | 1120 |

| B4 Distance between stoker and side of boiler | 600 | 600 | 600 | 600 | 600 |

| B5 Distance between flue gas pipe connection (opposite the stoker) and side of boiler | 290 | 290 | 290 | 290 | 290 |

| B6 Distance between flue gas pipe connection (opposite the control cabinet and control cabinet side) and side of boiler | 105 | 105 | 105 | 105 | 105 |

| B7 Distance between return connection and side of boiler | 1090 | 1090 | 1090 | 1090 | 1090 |

| W8 Distance between flow connection and side of boiler | 1475 | 1475 | 1475 | 1475 | 1475 |

| B9 Width of hydraulic stoker | 2710 | 2710 | 2710 | 2710 | 2710 |

| B10 Distance between the hydraulic stoker connection and side of boiler | 940 | 940 | 940 | 940 | 940 |

| H1 Height of inspection cover on the heat exchanger | 2690 | 2690 | 2690 | 2690 | 2690 |

| H2 Height of heat exchanger | 2350 | 2350 | 2350 | 2350 | 2350 |

| H3 Height of flue gas pipe connection (opposite the control cabinet) | 1670 | 1670 | 1670 | 1670 | 1670 |

| H4 Height of stoker connection (control cabinet side) | 1480 | 1480 | 1480 | 1480 | 1480 |

| H5 Height of stoker connection (opposite stoker) | 980 | 980 | 980 | 980 | 980 |

| H6 Height of stoker connection (screw-fed) | 945 | 945 | 945 | 945 | 945 |

| H7 Combustion chamber height | 2215 | 2215 | 2215 | 2215 | 2215 |

| H8 Height of connection for flow | 2300 | 2300 | 2300 | 2300 | 2300 |

| H9 Height of hydraulic stoker connection | 1160 | 1160 | 1160 | 1160 | 1160 |

| H10 Burn back slide valve | 1210 | 1210 | 1210 | 1210 | 1210 |

| H11 Height of return connection | 2215 | 2215 | 2215 | 2215 | 2215 |

For you personally

Information & advice

You would like to have further product information or you have general questions regarding our company?