WOOD CHIP BIOLER

20 – 350 kW

Integrated particle separator

(electrostatic precipitator)

available as an option

Wood chip boiler

T4e

User-friendly, compact, economical and safe:

The new T4e from Froling meets all your needs. With the silicon carbide combustion chamber, the

T4e ensures a high level of efficiency (up to 96.3%) with very low emissions. Well-planned use of energysaving EC drives ensures extremely low energy consumption.

Thanks to its modular construction and compact dimensions, the Froling T4e is particularly easy to position and install. The entire boiler comes fully assembled, electrically wired and tested.

Particular attention was paid to energy efficiency, durability and stability during the development of the T4e. The T4e consumes very little electricity during operation, keeping the operating costs

down. This priority was clearly confirmed when the boiler was awarded the EnergieGenie prize.

Information/advice

You would like to have further product information or you have general questions regarding our company?

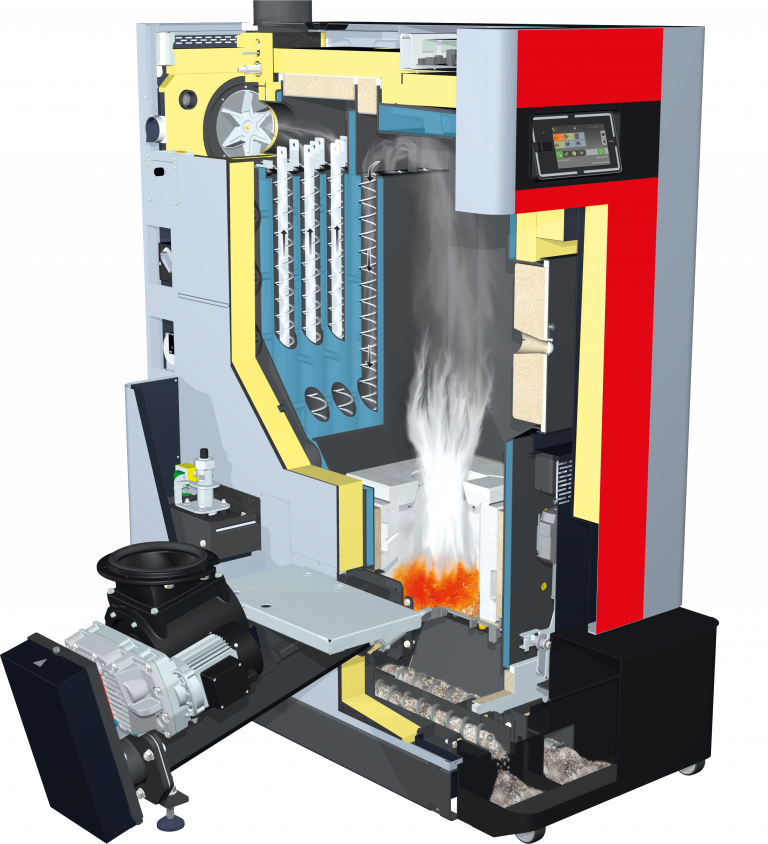

The latest technology

Rauchrohr auch mit hinterem Anschluss erhältlich (optional)

Lambdasonde für optimale Brennstoffanpassung

Drehzahlgeregeltes hocheffizientes EC-Saugzuggebläse für geringste Stromaufnahmen

Volumenoptimierte Ø 200 mm Zweikammer Zellradschleuse (Ø 240 mm bei T4e 300 - 350)

Stabiles Trittbrett für einfache Wartung und Montage (bis T4e 180 kW)

Stoker mit groß dimensionierter Ø100 mm Schnecke und ab 200 kW mit Ø150 mm Schnecke

7“ Touch-Display für leichte und intuitive Bedienung

Vollautomatische Reinigung aller Wärmetauscher-Rohre (schon ab dem ersten Zug) mittels Wirbulatoren (mechanischer Antrieb im „kalten“ Bereich)

Optimierte Siliziumkarbid Brennkammer für niedrigste Emissionen und eine lange Lebensdauer

Geräuschloser, stromeffizienter Keramikzünder mit Funktionsüberwachung

Unterdruckgeregelte Verbrennung mit sensorloser Glutbettüberwachung

Vollautomatische Entaschung mit stromsparendem Kombiantrieb (gemeinsamer Antrieb für Wärmetauscher- und Retortenascheschnecke) in großzügigen fahrbaren Aschebehälter

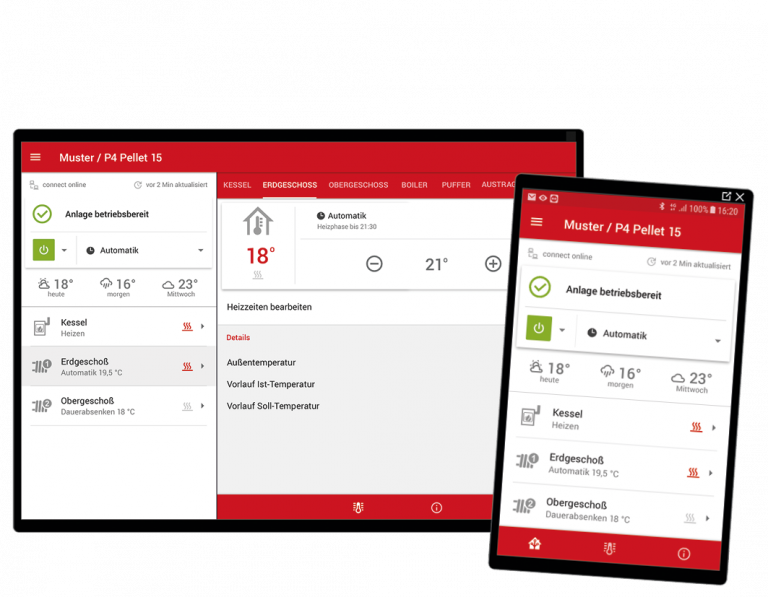

Individual control unit of the heating system

Lambdatronic 3200 control unit

Fröling provides a future-oriented Lambdatronic 3200 and a new 7“ touch display. Intelligent control management makes it possible to connect up to 18 heating circuits, up to 4 storage tanks and up to 8 hot water storage tanks. The control unit ensures that the operating statuses are clearly shown. The menu structure is ideally organised to allow easy operation. All essential functions can be selected by simply pressing icons on the large colour display.

Advantages:

- Precise combustion control by a Lambda control using a Lambda probe

- Connection for up to 18 heating circuits, 8 water heaters and up to 4 storage tank management systems

- Integration capability for a solar panel system

- LED frame for status display with illuminated presence detection

- Simple and intuitive operation

- Various smart home options (such as Loxone)

- Remote control from the living room (remote control 3200 and RGB 3200 Touch) or via Internet (froeling-connect.com)

Keep track of everything with the Froling App

The Froling App allows you to check and control your Froling boiler online from

anywhere, at any time. You can read and modify the main status information and settings easily and conveniently online. You can also specify which status messages you want to be informed about via SMS or e-mail (e.g. when the ash box is to be emptied or in the event of a fault message).

The app is available in the Android Play Store and iOS App Store.

Advantages

- Simple and intuitive operation of the boiler

- Status information can be called up and changed within seconds

- Individual naming of the heating circuits

- Changes of status are notified directly to the user (e.g. via

e-mail or push notifications) - No additional hardware required (such as an Internet gateway)

Smart Home

Loxone

Combine your Froling heating system with the Loxone Miniserver and the new Froling Extension and implement individual boiler control on the basis of the single room control of the Loxone Smart Home.

Modbus

Via the Froling modbus interface, the system can be integrated

into a building management system.

Prospekte / EU Label

Technical specifications

| Technische Daten - T4e | 20 | 25 | 30 | 35 | 45 | 50 | 60 | 80 | < 80 |

|---|---|---|---|---|---|---|---|---|---|

| Nennwärmeleistung [kW] | 19,9 | 25,1 | 30 | 35 | 45 | 49,9 | 60 | 80 | ~#i#~ |

| Wärmeleistungsbereich [kW] | 5,95 - 19,9 | 7,51 - 25,1 | 9 - 30 | 10,5 - 35 | 13,5 - 45 | 14,9 - 49,9 | 18 - 60 | 24 - 80 | ~#i#~ |

| Gewicht des Kessels (inkl. Stoker ohne Wasserinhalt) [kg] | 740 | 740 | 740 | 740 | 850 | 850 | 850 | 1160 | ~#i#~ |

| Zulässiger Brennstoff gem. EN ISO 172251) | Teil 2: Holzpellets Klasse A1 / D06<br>Teil 4: Holzhackschnitzel Klasse A2 / P16S-P31S Deutschland zusätzlich: Brennstoffklasse 4 (§3 der 1. BlmSchV i.d.g.F) | Teil 2: Holzpellets Klasse A1 / D06<br>Teil 4: Holzhackschnitzel Klasse A2 / P16S-P31S Deutschland zusätzlich: Brennstoffklasse 4 (§3 der 1. BlmSchV i.d.g.F) | Teil 2: Holzpellets Klasse A1 / D06<br>Teil 4: Holzhackschnitzel Klasse A2 / P16S-P31S Deutschland zusätzlich: Brennstoffklasse 4 (§3 der 1. BlmSchV i.d.g.F) | Teil 2: Holzpellets Klasse A1 / D06<br>Teil 4: Holzhackschnitzel Klasse A2 / P16S-P31S Deutschland zusätzlich: Brennstoffklasse 4 (§3 der 1. BlmSchV i.d.g.F) | Teil 2: Holzpellets Klasse A1 / D06<br>Teil 4: Holzhackschnitzel Klasse A2 / P16S-P31S Deutschland zusätzlich: Brennstoffklasse 4 (§3 der 1. BlmSchV i.d.g.F) | Teil 2: Holzpellets Klasse A1 / D06<br>Teil 4: Holzhackschnitzel Klasse A2 / P16S-P31S Deutschland zusätzlich: Brennstoffklasse 4 (§3 der 1. BlmSchV i.d.g.F) | Teil 2: Holzpellets Klasse A1 / D06<br>Teil 4: Holzhackschnitzel Klasse A2 / P16S-P31S Deutschland zusätzlich: Brennstoffklasse 4 (§3 der 1. BlmSchV i.d.g.F) | Teil 2: Holzpellets Klasse A1 / D06<br>Teil 4: Holzhackschnitzel Klasse A2 / P16S-P31S Deutschland zusätzlich: Brennstoffklasse 4 (§3 der 1. BlmSchV i.d.g.F) | ~#i#~ |

¹ Achtung: Bei T4e 20-110 befinden sich der Vor- und Rücklaufanschluss auf Seite des Stokers, der Rauchrohranschluss hinten (Option) wird auf der abgewandten Seite des Stokers montiert.

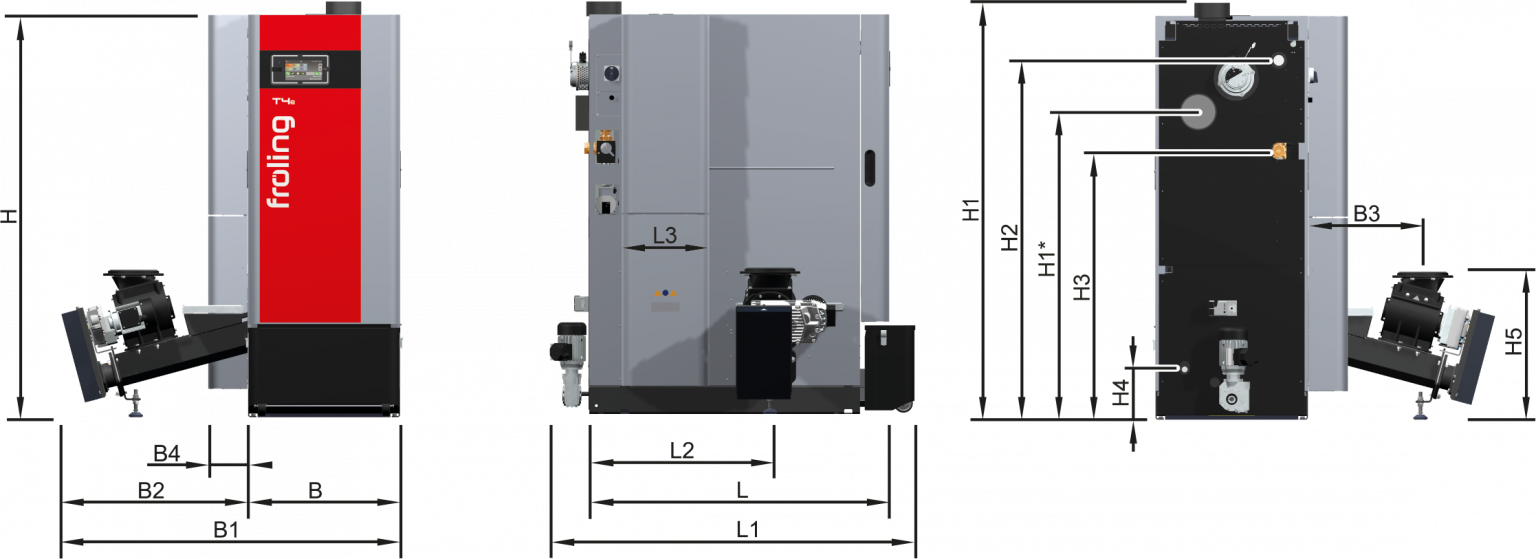

Abmessungen

| Abmessungen [mm] | 20 - 35 | 45 - 60 | < 80 |

|---|---|---|---|

| H Kesselhöhe | 1490 | 1690 | ~#i#~ |

| B Kesselbreite<br>Breite ohne Isolierung (Einbringbreite) | 640<br>- | 640<br>- | ~#i#~ |

| B1 Gesamtbreite mit Stokereinheit | 1410 | 1410 | ~#i#~ |

| B2 Breite Stokereinheit | 770 | 770 | ~#i#~ |

| B4 Breite Partikelabscheider/Elektrofilter (optional) | 165 | 165 | ~#i#~ |

| L Kessellänge | 1170 | 1270 | ~#i#~ |

| L1 Gesamtlänge | 1475 | 1550 | ~#i#~ |

| L2 Länge Kesselrückseite zu Stokeranschluss | 690 | 770 | ~#i#~ |

¹ Achtung: Bei T4e 20-110 befinden sich der Vor- und Rücklaufanschluss auf Seite des Stokers, der Rauchrohranschluss hinten (Option) wird auf der abgewandten Seite des Stokers montiert.

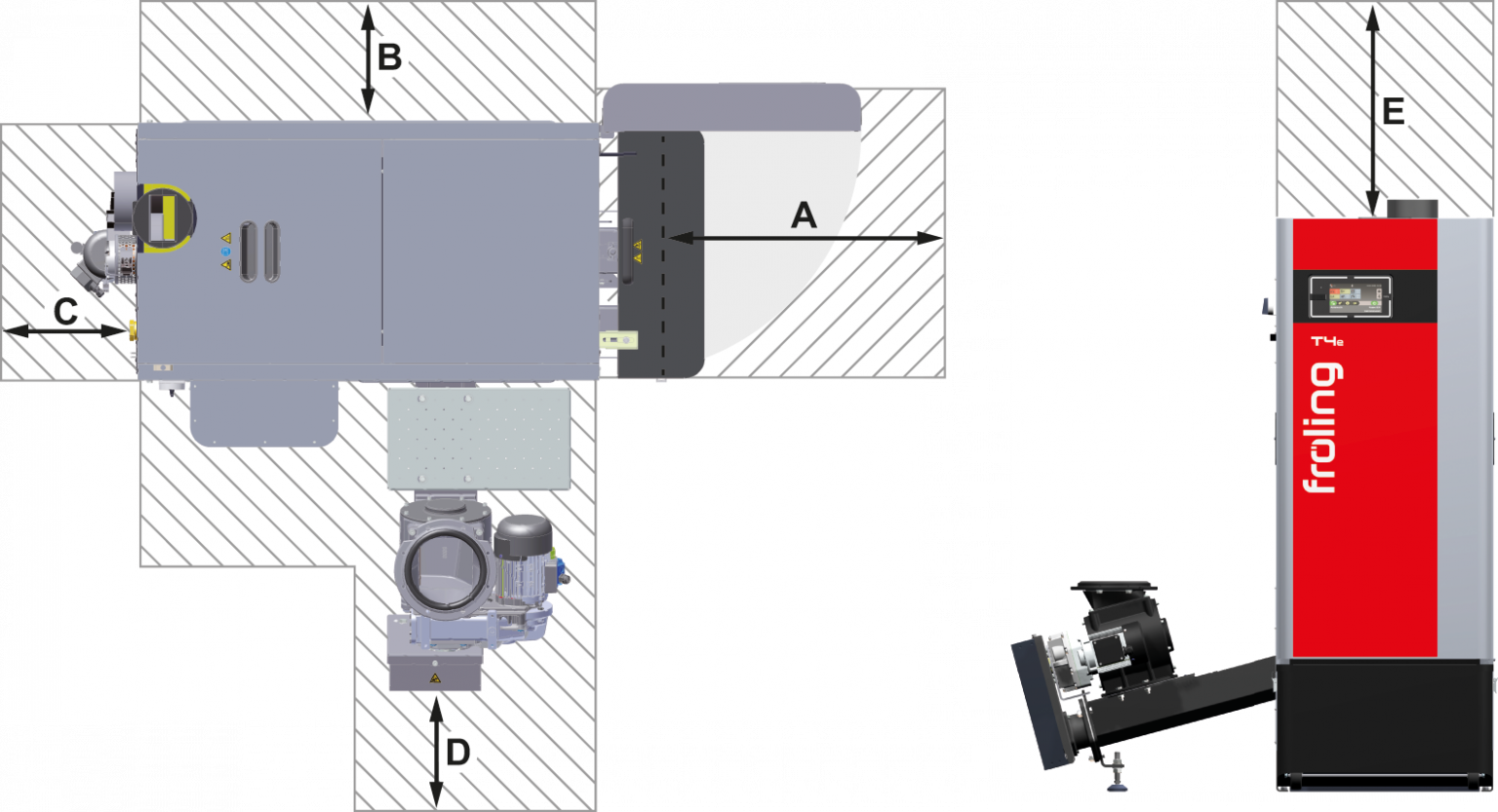

Bedienungs- und Wartungsbereiche

| Mindestabstände [mm] | 20 | 25 | 30 | 35 | 45 | 50 | 60 | 80 | <80 |

|---|---|---|---|---|---|---|---|---|---|

| A Isoliertür zur Wand | 700 | 700 | 700 | 700 | 700 | 700 | 700 | 800 | ~#i#~ |

| B Kesselseite zur Wand | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | ~#i#~ |

| C Kesselrückseite zur Wand | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | ~#i#~ |

| D Stoker zur Wand | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | ~#i#~ |

| E Wartungsbereich über dem Kessel | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | ~#i#~ |

| Mindestraumhöhe | 1800 | 1800 | 1800 | 1800 | 2000 | 2000 | 2000 | 2100 | ~#i#~ |

¹ Wartungen am Wärmetauscher des Kessels nur von vorne möglich

² Wartungsbereich zum Ausbau der WOS-Federn nach oben

Technische Dokumente

For you personally

Information & advice

You would like to have further product information or you have general questions regarding our company?

Zufriedene Kunden

Unsere Referenzen

Ob Häuslbauer oder Renovierer, unsere zufriedenen Kunden setzen auf die Heizkessel aus unserem Familienbetrieb. Überzeugen Sie sich selbst und finden Sie mit uns die für Sie beste Heizlösung!

Duis porta nisl eu libero elementum, porttitor lobortis purus condimentum.

Frida Fröling

Duis porta nisl eu libero elementum, porttitor lobortis purus condimentum.

Frida Fröling

Duis porta nisl eu libero elementum, porttitor lobortis purus condimentum.

Frida Fröling

Fertiggestellte Projekte

Professionelle Teams