PELLET BOILER

12 – 105 kW

UNIQUE, INNOVATIVE.

Electrostatic precipitator

can be integrated

Pellet boiler

NEW! P5 Pellet

The newly developed P5 Pellet can be equipped with an optional electrostatic particle separator, which minimises dust emissions.

Thanks to the integrated return temperature control, the boiler always runs within the optimal temperature range, thus increasing efficiency.

Information/advice

You would like to have further product information or you have general questions regarding our company?

The latest technology

Optional integrable electrostatic precipitator

Continuously integrated return temperature control

without a mixing valve for maximum efficiency

Innovative ash flap

WOS system Efficiency Optimisation System

High-temperature cast steel combustion chamber with tangential secondary air nozzles for even better combustion

High-quality insulation for minimal radiant heat loss

Power-saving ceramic glow igniter for minimised energy consumption

Lambdatronic 5000 controller with 7" glass touch display for easy and intuitive operation

Automatic ash removal into a closed ash container

Patented slatted tipping grate with automatic grate cleaning

Individual controller for the heating system

Lambdatronic 5000 controller

With the new Lambdatronic 5000 boiler controller and the modern 7″ glass touch display, Fröling is moving into the future. The new design is impressive, not only for its intuitive operation but also its numerous new features. The most important

components can be freely selected in the tile overview and information and error messages can be customised. For example, the control system will inform you when the ash box needs to be emptied. This makes operating and running the system even simpler and easier to understand. The intelligent control management enables the almost unlimited integration of heating circuits, storage tanks and hot water tanks.

Advantages

- Precise combustion control by a Lambda controller using a Lambda probe

- Connection of heating circuits, water heaters and buffer storage tanks Management systems

- Integration capability for a solar panel system

- LED frame for status display with illuminated presence detection

- Simple & intuitive operation

- Various SmartHome solutions (e.g. Loxone, Modbus TCP) Remote control from the Living room (room console) or via the Internet (froeling-connect.com)

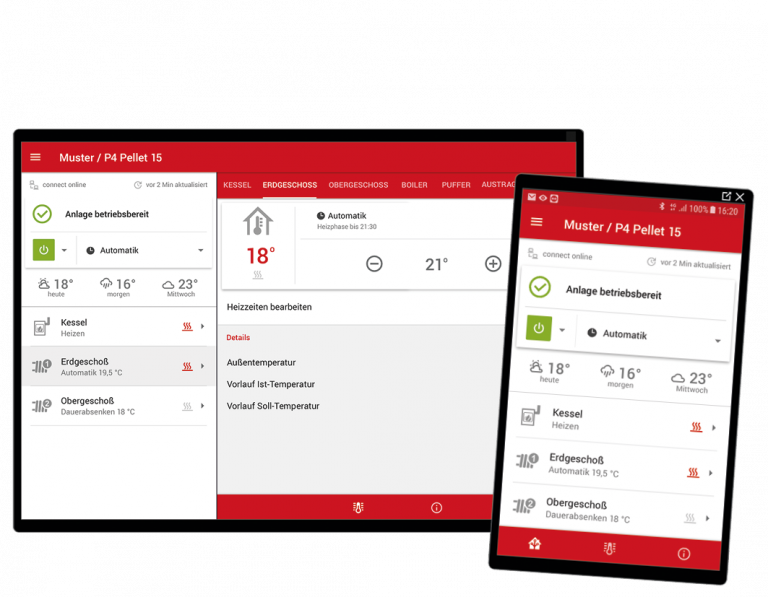

Keep track of everything with the Froling App

The Froling App allows you to check and control your Froling boiler online from

anywhere, at any time. You can read and modify the main status information and settings easily and conveniently online. You can also specify which status messages you want to be informed about via SMS or e-mail (e.g. when the ash box is to be emptied or in the event of a fault message).

The app is available in the Android Play Store and iOS App Store.

Advantages

- Simple and intuitive operation of the boiler

- Status information can be called up and changed within seconds

- Individual naming of the heating circuits

- Changes of status are notified directly to the user (e.g. via

e-mail or push notifications) - No additional hardware required (such as an Internet gateway)

Smart Home

Loxone

Combine your Froling heating system with the Loxone Miniserver and the new Froling Extension and implement individual boiler control on the basis of the single room control of the Loxone Smart Home.

Modbus

Via the Froling modbus interface, the system can be integrated

into a building management system.

Brochures / EU Label

Technical specifications

| Tecnical specifications - P5 Pellet | 12 | 15 | 18 | 20 | > 20 |

|---|---|---|---|---|---|

| Rated heat output¹ [kW] | 12 | 14,9 | 18 | 20 | Details for P5 20 - 105 kW please take a look in our brochures |

| Power consumption (nominal load) [W] | 55 | 58 | 62 | 65 | |

| Energy label² | A++ | A++ | A++ | A++ | |

| Electrical connection [V/Hz/A] | 230 V / 50 Hz / fused C16A | 230 V / 50 Hz / fused C16A | 230 V / 50 Hz / fused C16A | 230 V / 50 Hz / fused C16A | |

| Weight [kg] | 260 | 260 | 260 | 260 | |

| Boiler capacity (water) [l] | 30 | 30 | 30 | 30 | |

| Pellet container capacity [l] | 55 | 55 | 55 | 55 | |

| Capacity, ash container [l] | 16 | 16 | 16 | 16 |

¹ Please note the eligible storage tank content for Germany! Please observe the subsidy regulations with regard to the required storage tank (eligibility).

2 Efficiency label (boiler + controller + condenser)

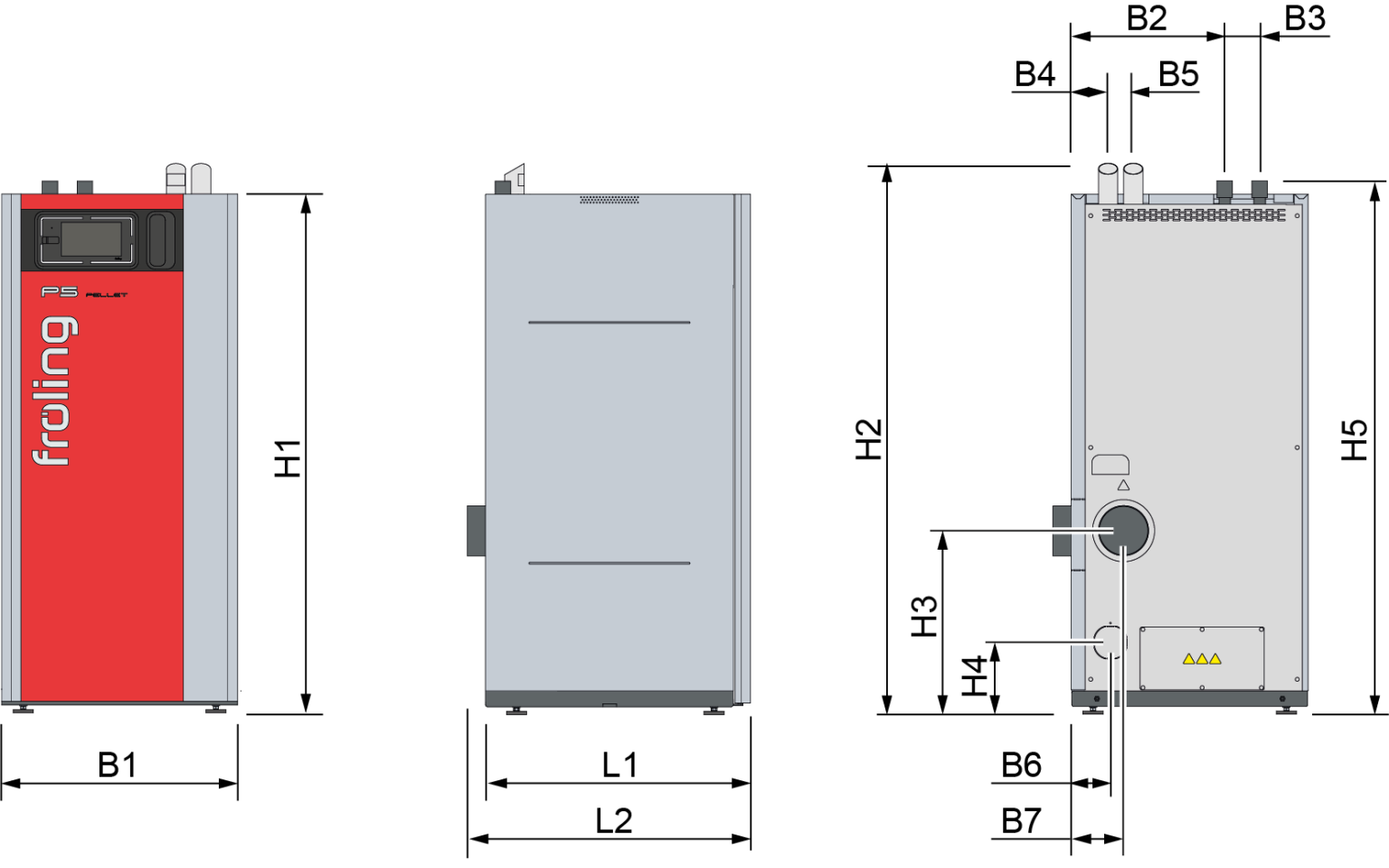

Dimensions

| Dimensions in mm - P5 Pellet | 12-20 | 25-40 | > 45 |

|---|---|---|---|

| L1 Length, boiler | 685 | 750 | Details for P5 45 - 105 kW please take a look in our brochures |

| L2 Total length incl. flue gas pipe connection | 730 | 795 | |

| B1 Width of boiler | 610 | 700 | |

| B2 Distance of the flow to the side of the boiler | 395 | 485 | |

| B3 Distance flow/return | 90 | 90 | |

| B4 Distance between the suction lines and the side of the boiler | 95 | 115 | |

| B5 Distance of suction hose connections | 65 | 65 | |

| B6 Distance of the supply air to the side of the boiler | 105 | 100 | |

| B7 Distance of the flue gas pipe connection from the side of the boiler | 135 | 180 | |

| H1 Height, boiler | 1340 | 1560 | |

| H2 Height of suction hose connections | 1420 | 1640 | |

| H3 Height of rear flue gas pipe connection (optional) | 475 | 560 | |

| H4 Height of supply air line | 115 | 200 | |

| H5 Height, flow/return connection | 1375 | 1595 | |

| Flue spigot diameter, outside | 129 | 129 |

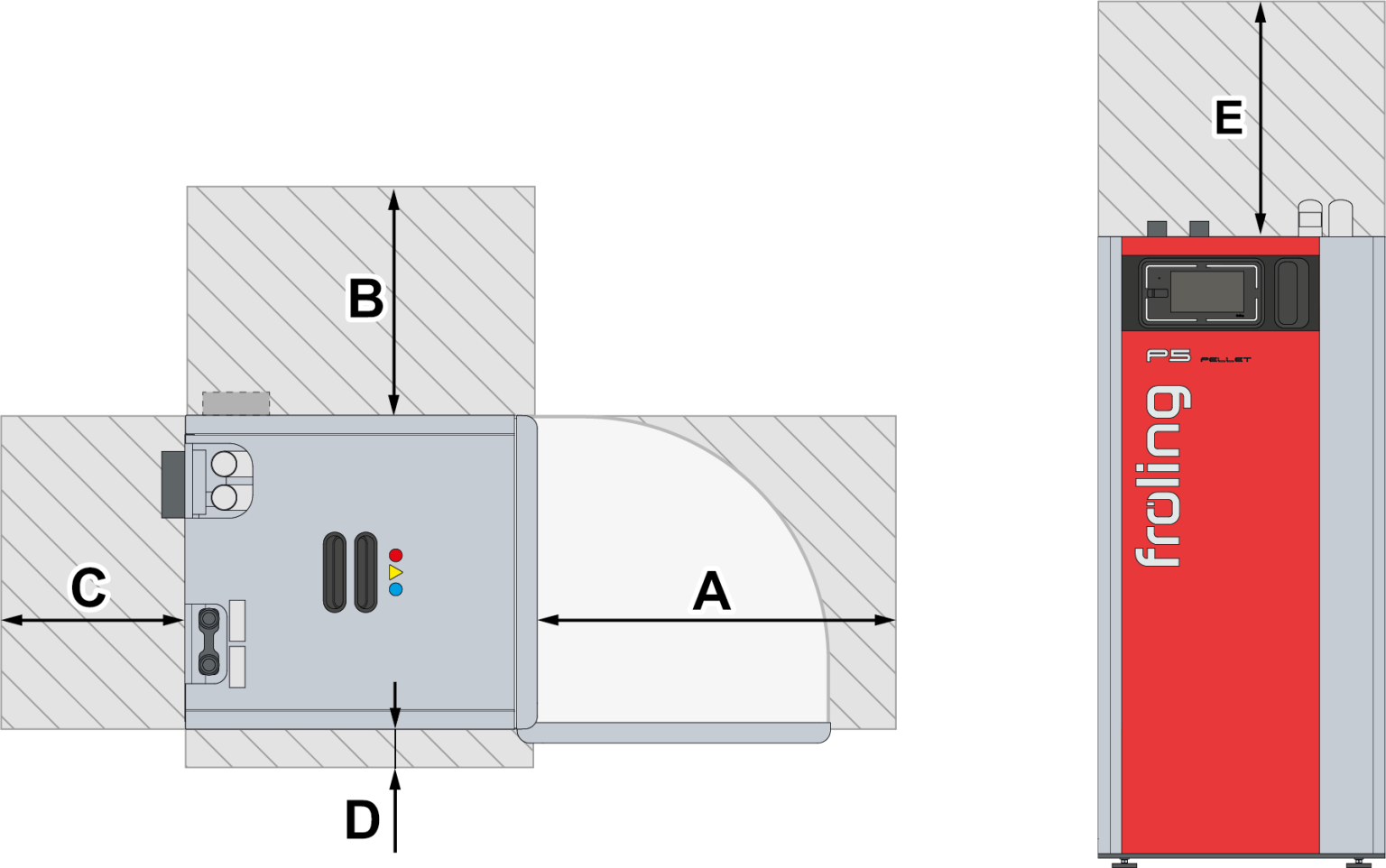

Operating and maintenance areas

| Recommended distances in mm - P5 Pellet | 12-20 | 25-40 | > 45 |

|---|---|---|---|

| A Insulated door to the wall | 600 | 690 | Details for P5 20 - 105 kW please take a look in our brochures |

| B Side of the boiler to the wall | 500 | 500 | |

| C Rear to the wall (flue gas pipe at the back) | |||

| Rear to the wall (flue gas pipe at the side) | 400<br> | 300<br> | |

| Rückseite zur Wand (Abgasrohr seitlich) | 50¹ | 50¹ | |

| D Side of the boiler to the wall | 30 | 30 | |

| E Maintenance area above the boiler for removing the WOS springs upwards | 500 | 500 | |

| Minimum room size (L x W) | 1335 x 1140 | 1490 x 1230 |

¹ With the flue gas pipe connection at the right-hand side of the boiler (conversion necessary)

2 Maintenance area for removing the WOS springs upwards

Technical documentation

For you personally

Information & advice

You would like to have further product information or you have general questions regarding our company?