WOOD CHIP AND PELLET BOILER

150 – 550 kW

- Sturdy construction

- Industrial model

Wood chip and pellet boiler

Turbomat

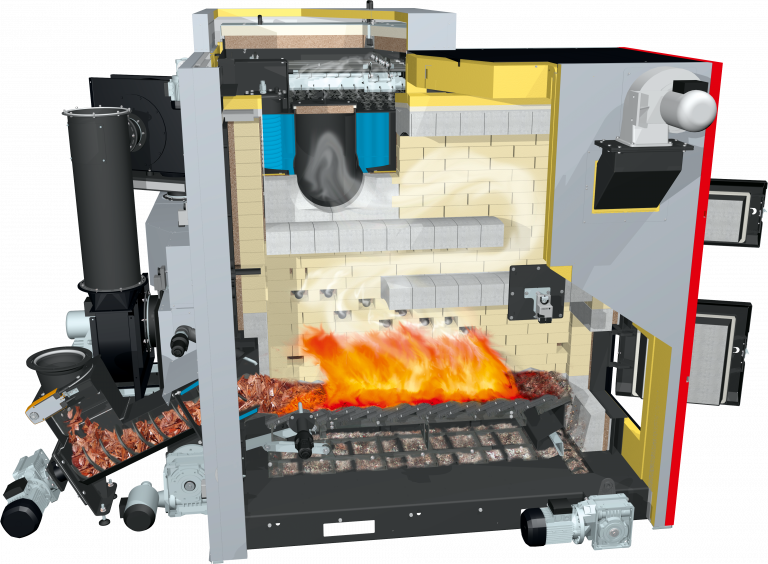

Froling’s Turbomat is a unique heating system with a fully automatic wood burner which will operate with a wide variety of wooden material. As a leading manufacturer of biomass heating systems, the Turbomat embodies all of Froling’s expertise in pioneering innovation. We were looking for a boiler that would be perfectly suited for burning other biomass fuels as well as wood chips.

The Turbomat not only boasts innovative combustion technology but also offers impressive control options. With Lambda controls as standard, combustion chamber temperature monitoring and under-pressure control, perfect combustion is guaranteed for a range of materials. The comfort provided sets new standards in this performance category.

All Turbomat functions are fully automatic, from fuel feed and combustion right through to cleaning and ash removal. The high-tech Turbomat is designed to be extremely robust, durable and easy to service.

Information/advice

You would like to have further product information or you have general questions regarding our company?

The latest technology

TM 150/200/250

Vertical 3-pass heat exchanger and Efficiency Optimisation System WOS)

with automatically operated turbulators for cleaning and for minimal dust emissions (<50 mg/Nm³)

Flue gas recirculation FGR

optimises burning (output, emissions etc.) with particularly demanding fuels, e.g. pellets, shavings, miscanthus etc...

Speed-regulated and function-

monitored induced draught fan

together with the under-pressure

controller ensure that the system

continuously adapts to changes in

fuel and the chimney conditions

Trapezoidal stoker duct

guarantees minimal energy consumption in the feed area and full flexibility for varying fuel sizes. The industry standard drive gear unit is durable and mechanically isolated from the feed channel.

This prevents the screw movements from affecting the gear unit.

A bonus feature of the TM 200/250 is also the fact that the feed area is water-cooled in the high temperature range. This serves the very practical purpose of pre-drying the heating material where the fuel has a high moisture content.

4-layer high temperature combustion chamber

(firebrick / insulation 1 / air jacket / insulation 2) made of premium, heat-resistant fireclay components for optimal combustion, even with inferior fuel (e.g. high moisture level etc.) or alternative fuel

Multilayer thermal insulation guarantees minimum radiant heat

Large, solid combustion chamber doors

ensure ease of access for maintenance

Moving grate

for constantly homogeneous combustion process with ongoing removal of combustion residue

Automatic ash removal

for transport into adjacent ash containers

TM 320 / 400 / 500

Vertical, patented 4-pass heat exchanger

with integrated suction cyclone unit dust separation unit and Efficiency Optimisation System (WOS) with automatic cleaning function. Operating pressure up to 6 bar.

Flue gas recirculation FGR

optimises burning (output, emissions etc.) with particularly demanding fuels, e.g. pellets, shavings, miscanthus etc...

Speed-regulated and function-monitored

induced draught fan

together with the under-pressure controller ensure that the system continuously adapts to changes in fuel and the chimney conditions

Trapezoidal stoker duct

guarantees minimal energy consumption in

the feed area and full flexibility for varying fuel sizes. The industry standard drive gear unit is durable and mechanically isolated from the feed channel. This prevents the screw movements from affecting the gear unit. A

bonus feature is also the fact that the feed area is water-cooled in the high temperature

range. This serves the very practical purpose of pre-drying the heating material where the fuel has a high moisture content.

Second ignition fan

for heating material that is hard to light (e.g. damp)

Second ignition fan

for heating material that is hard to light (e.g. damp)

Case cooling of combustion chamber minimises radiant heat

High-temperature post combustion

zone

with hot fireclay lining prolongs combustion. This increases efficiency even further, particularly with inferior fuels.

4-layer high temperature combustion chamber (firebrick / insulation 1 / air jacket / insulation 2) made of premium, heat-resistant fireclay components for optimal combustion,

even with inferior fuel (e.g. high moisture level etc.) or alternative fuel

Large, solid combustion chamber doors

ensure ease of access for maintenance

Moving grate for constantly homogeneous combustion process with ongoing removal of combustion residue.

The innovative primary air zone separation system produces exceptional combustion results with low CO emissions!

Systematic convenience

The PLC 4000 controller is built using high-quality industry-standard components. The clear, user-friendly control system offers a wide range of different settings and visualisation options for individual, efficient and stable operation. The Froling PLC 4000 offers numerous functional options such as multi-sensor storage tank management, heating circuit and network temperature control, external output specifications, cascade function, integration, monitoring and control of additional peripheral components.

Advantages

Powerful PLC controller with big colour touch display

Simple and reliable remote access via Froling visualisation software

Numerous functional options

Brochures / EU Label

Technical specifications

| Technical specifications - Turbomat | 150 | 200 | 250 | 320 | 400 | 500 | 550 |

|---|---|---|---|---|---|---|---|

| Nominal heat output [kW] | 150 | 199 | 250 | 320 | 399 | 499 | 550 |

| Flue pipe diameter [mm] | 200 | 250 | 250 | 300 | 350 | 350 | 350 |

| Total dry weight including attachments [kg] | 3300 | 3820 | 3820 | 6330 | 8470 | 8470 | 8470 |

| Heat exchanger water capacity [l] | 440 | 570 | 570 | 780 | 1040 | 1040 | 1040 |

| Maximum permitted operating temperature [°C] | 90 | 90 | 90 | 90 | 90 | 90 | 90 |

| Minimum boiler return temperature [°C] | 65 | 65 | 65 | 65 | 65 | 65 | 65 |

| Maximum permitted working over-pressure [bar] | 4 | 4 | 4 | 6 | 6 | 6 | 6 |

| Flue gas temperature (NL / PL) [°C] | 150/110 | 150/110 | 150/110 | 140 / 110 | 140 / 110 | 140 / 110 | 140 / 110 |

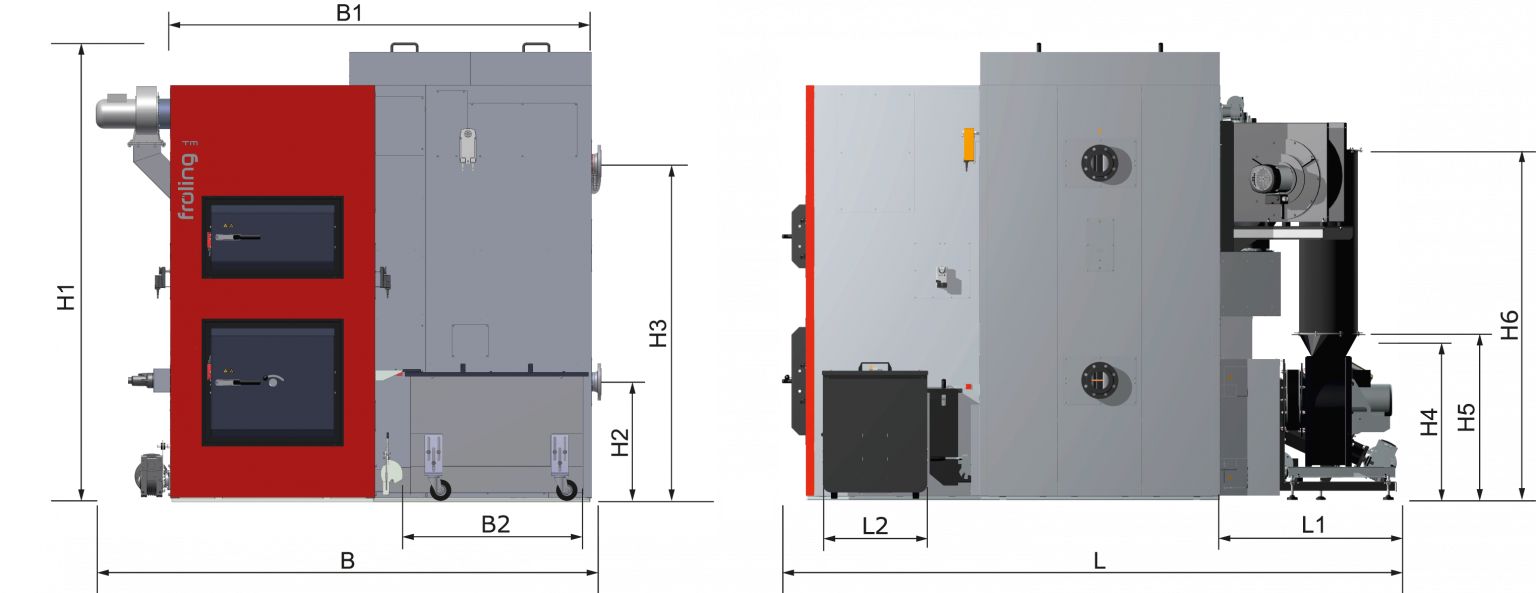

Dimensions

| Dimensions - Turbomat [mm] | 150/200/250 | 320 | 400/500/550 |

|---|---|---|---|

| H1 Boiler height including insulation | ~#i#~ | 2560 | 2660 |

| H2 Height of return connection | ~#i#~ | 640 | 710 |

| H3 Height of flow connection | ~#i#~ | 1850 | 2000 |

| H4 Height of stoker including burn back protection system | ~#i#~ | 815 | 930 |

| H5 Height, flue gas pipe connection without FGR | ~#i#~ | 960 | 985 |

| H6 Height, flue gas pipe connection with FGR | ~#i#~ | 2005 | 2075 |

| B Total width including fittings | ~#i#~ | 2780 | 2990 |

| B1 Width, boiler including insulation | ~#i#~ | 2195 | 2495 |

| B2 Width, combustion chamber ash containere | ~#i#~ | 730 | 1165 |

| L Total length including fittingse | ~#i#~ | 3340 | 3595 |

| L1 Length, stoker unit | ~#i#~ | 940 | 1050 |

| L2 Length, combustion chamber ash container | ~#i#~ | 600 | 630 |

Technical documentation

For you personally

Information & advice

You would like to have further product information or you have general questions regarding our company?