FIREWOOD BOILER

15 – 20 kW

Optional with retro-

fittable pellet unit

Firewood boiler

S1 Turbo

The S1 Turbo (15 – 20 kW) combines all the features of a state-of-the-art biomass combustion system. The speed-regulated induced draught fan ensures constant high quality combustion, and the carbonisation gas extraction system prevents flue gas from escaping, even when topping up. The new S1 Turbo stands out for its high efficiency and long refilling intervals, as well as its low emissions and low energy consumption. The new air duct concept in Froling’s S1 Turbo firewood boiler automatically regulates the heating, primary and secondary air with a single actuator. Thanks to the special air ducts for pre-heating, the fuel loading chamber door can be closed very soon after lighting. Heating with firewood can be that convenient!

The S1 Turbo F with pellet flange is the ideal solution for people who are currently only burning firewood. With the S1 Turbo F with pellet flange, the pellet unit can be retrofitted later at any time.

Information/advice

You would like to have further product information or you have general questions regarding our company?

The latest technology

Speed-regulated induced draught fan

Suspension lip to protect the inner wall of the boiler and guarantee that the logs slide through

Heat exchanger pipes for optimum cleaning

WOS system Efficiency Optimisation System

Optional integrable electrostatic precipitator with cleaning basket

Large fuel loading chamber for half metre logs (up to 56 cm)

High-temperature firebrick-lined combustion chamber (easy to replace individual bricks)

High-quality insulation for minimal radiant heat loss

7” touch display for simple and intuitive operation

Carbonisation gas extraction system prevents smoke escaping during reloading

Air-cooled fuel loading chamber and cleaning door to minimise radiant heat loss

Special automatic pre-heating with regulated air ducts

Servo-motor for automatic control of heating, primary and secondary air

Large cleaning port door for easy ash removal and cleaning from the front

Individual control unit of the heating system

Lambdatronic 3200 control unit

Fröling provides a future-oriented Lambdatronic 3200 and a new 7“ touch display. Intelligent control management makes it possible to connect up to 18 heating circuits, up to 4 storage tanks and up to 8 hot water storage tanks. The control unit ensures that the operating statuses are clearly shown. The menu structure is ideally organised to allow easy operation. All essential functions can be selected by simply pressing icons on the large colour display.

Advantages:

- Precise combustion control by a Lambda control using a Lambda probe

- Connection for up to 18 heating circuits, 8 water heaters and up to 4 storage tank management systems

- Integration capability for a solar panel system

- LED frame for status display with illuminated presence detection

- Simple and intuitive operation

- Various smart home options (such as Loxone)

- Remote control from the living room (remote control 3200 and RGB 3200 Touch) or via Internet (froeling-connect.com)

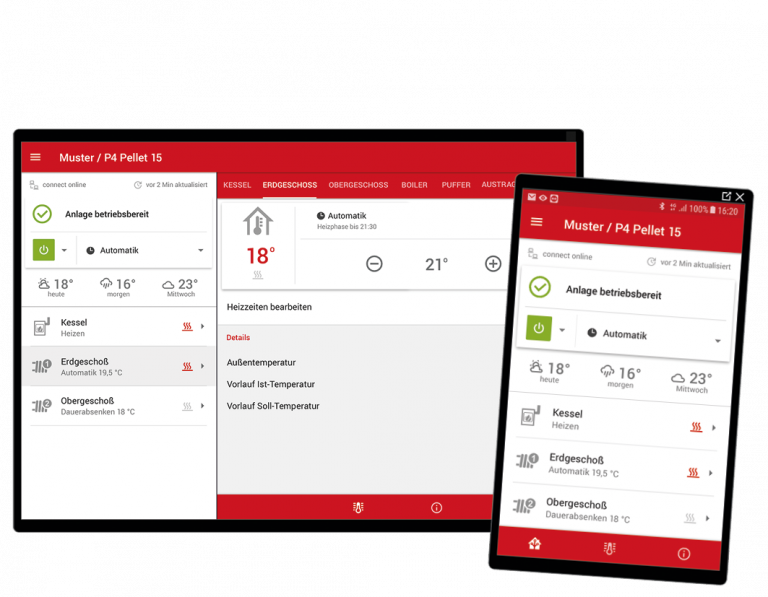

Keep track of everything with the Froling App

The Froling App allows you to check and control your Froling boiler online from

anywhere, at any time. You can read and modify the main status information and settings easily and conveniently online. You can also specify which status messages you want to be informed about via SMS or e-mail (e.g. when the ash box is to be emptied or in the event of a fault message).

The app is available in the Android Play Store and iOS App Store.

Advantages

- Simple and intuitive operation of the boiler

- Status information can be called up and changed within seconds

- Individual naming of the heating circuits

- Changes of status are notified directly to the user (e.g. via

e-mail or push notifications) - No additional hardware required (such as an Internet gateway)

Smart Home

Loxone

Combine your Froling heating system with the Loxone Miniserver and the new Froling Extension and implement individual boiler control on the basis of the single room control of the Loxone Smart Home.

Modbus

Via the Froling modbus interface, the system can be integrated

into a building management system.

Brochures / EU Label

Technical specifications

| Technical specifications - S1 Turbo | 15 | 20 |

|---|---|---|

| Nominal output [kW] | 15 | 20 |

| Energy label* | A + | A + |

| Electrical connection [V/Hz/A] | 230V / 50Hz / fused C16A | 230V / 50Hz / fused C16A |

| Power consumption at nominal load [W] | 37 | 42 |

| Weight of boiler incl. insulation and control [kg] | 455 | 465 |

| Fuel loading door dimensions (width / height) [mm] | 350 / 360 | 350 / 360 |

| Total boiler capacity (water) [l] | 80 | 80 |

* Configuration label (boiler + control + calorific value)

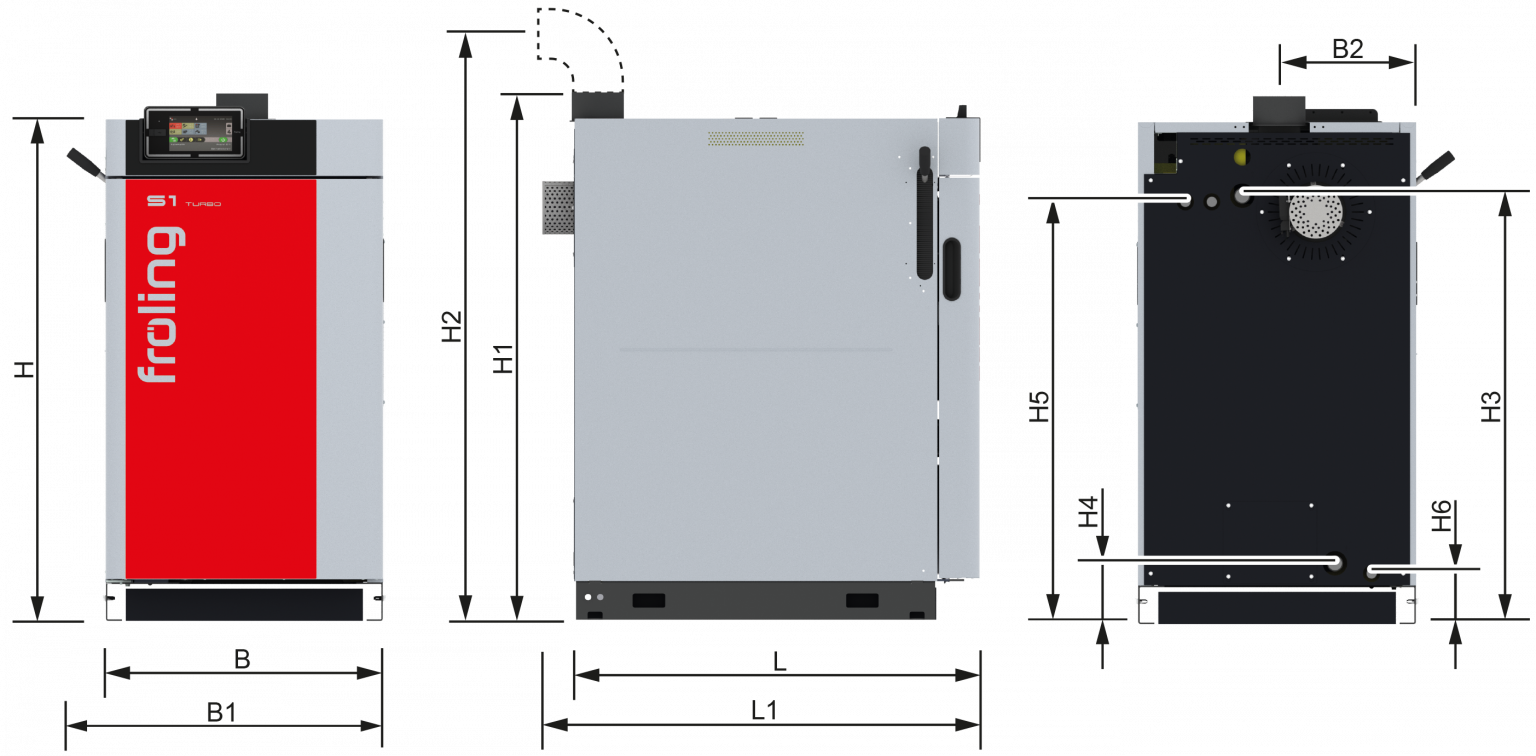

Dimensions

| Dimensions - S1 Turbo [mm] | 15 / 20 |

|---|---|

| L Length of boiler | 1000 |

| L1 Total length incl. induced draught fan | 1080 |

| B Width, boiler | 685 |

| B1 Width of boiler incl. WOS lever | 790 |

| B2 Clearance from flue pipe connection to side of boiler | 340 |

| H Height, boiler | 1235 |

| H1 Total height including flue pipe nozzle | 1300 |

| H2 Height flue pipe connection¹ | 1395 |

| H3 Height, flow connection | 1055 |

| H4 Height, return connection | 150 |

| H5 Height, safety heat exchanger connection | 1040 |

| H6 Height, drainage connection | 125 |

| Flue pipe diameter | 129 |

¹ When using the optional flue pipe nozzle for low chimney connections

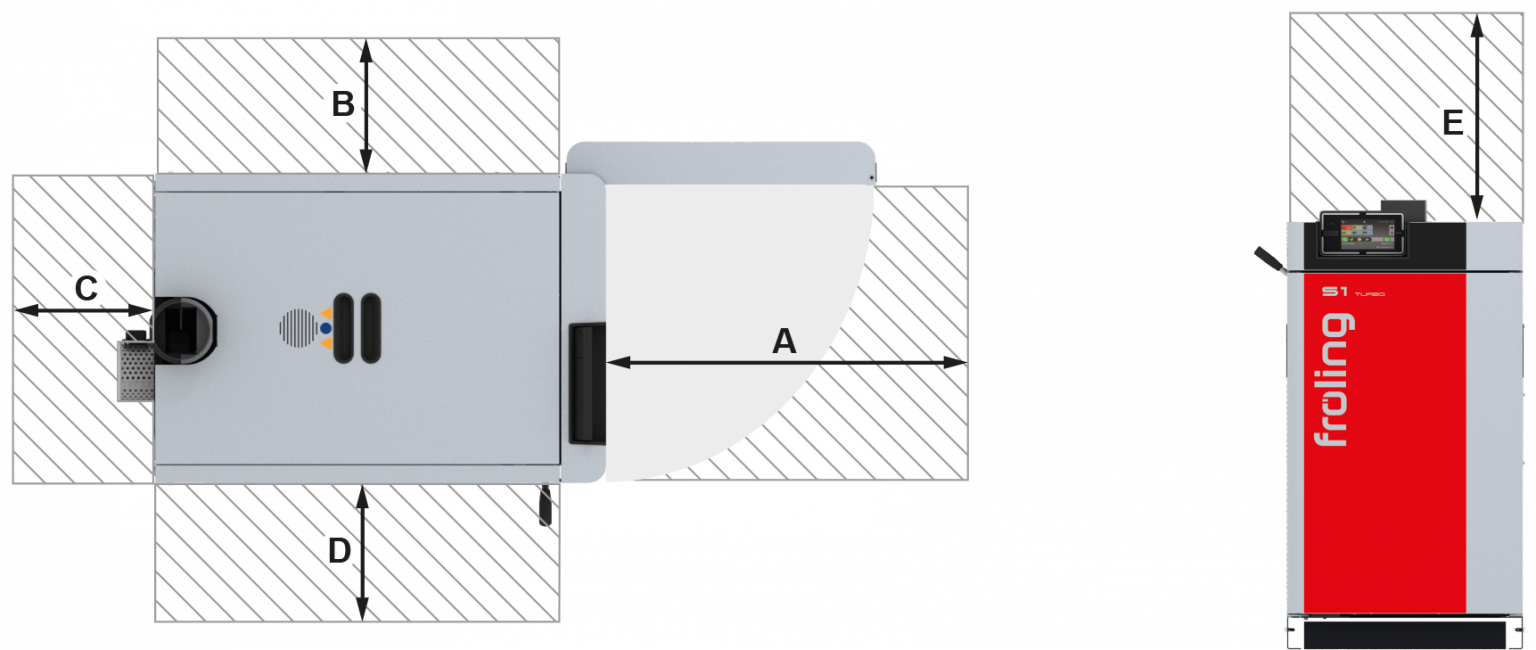

Operating and maintenance areas

| Minimum distances - S1 Turbo [mm] | 15 / 20 |

|---|---|

| A Distance between front of boiler and wall | 800 |

| B Distance between side of boiler and wall | 200 |

| C Distance between rear of boiler and wall | 400 |

| D Distance between side of boiler and wall | 500 (200¹) |

| E Maintenance area to expand the WOS springs upwards | 500 |

| Minimum distances - S1 Turbo F (SP Dual compact) [mm] | 15 / 20 |

|---|---|

| A Distance between front of boiler and wall | 800 |

| B Distance between side of boiler with heat exchanger lever and pellet unit and wall | 200 |

| B1 Distance between side of boiler without pellet unit and wall | 815 |

| C Distance between rear of boiler and wall | 400 |

| D Distance between side of boiler with WOS lever and wall | 500 (200¹) |

| E Maintenance area to expand the WOS springs upwards | 500 |

¹ Maintenance work to boiler’s heat exchanger only possible from front

Technical documentation

For you personally

Information & advice

You would like to have further product information or you have general questions regarding our company?