PELLET BOILER

7 – 35 kW

UNIQUE, INNOVATIVE.

Condensing technology

for pellet boilers

Pellet boiler

PE1 Pellet

Occupying just 0.38 m² of space, the PE1 Pellet boiler sets new standards. The new PE1 Pellet stands out for its quiet operation and ease of use, combined with low emissions and very low energy consumption. Thanks to its high energy efficiency the PE1 Pellet is particularly suitable for low-energy and passive houses.

The compact solution for the boiler room

A unique design: The new PE1 Pellet is optionally available with DHW tank block for hot water and hydraulic block with heating circuit pumps, heating circuit mixing valve and DHW tank loading. These two modules make the PE1 Pellet the compact all-round solution for the boiler room.

Information/advice

You would like to have further product information or you have general questions regarding our company?

The latest technology

Speed-controlled, quiet induced-draught fan with function monitor

Broadband lambda probe for optimal combustion

WOS system Efficiency Optimisation System

High-quality pellet burner

High-quality insulation

Automatic sliding grate for ash removal

7” touch display for easy and intuitive operation

Generously dimensioned pellet container

Double protection system for maximum burn back protection

Double protection system for maximum burn back protection

Combustion air supply (optional independent of ambient air)

Automatic ignition

Automatic ash removal in a closed ash container (Ash container volume: 13 litres with 7 - 10 kW, 28 litres with 25 - 35 kW) .

Individual control unit of the heating system

Lambdatronic 3200 control unit

Fröling provides a future-oriented Lambdatronic 3200 and a new 7“ touch display. Intelligent control management makes it possible to connect up to 18 heating circuits, up to 4 storage tanks and up to 8 hot water storage tanks. The control unit ensures that the operating statuses are clearly shown. The menu structure is ideally organised to allow easy operation. All essential functions can be selected by simply pressing icons on the large colour display.

Advantages:

- Precise combustion control by a Lambda control using a Lambda probe

- Connection for up to 18 heating circuits, 8 water heaters and up to 4 storage tank management systems

- Integration capability for a solar panel system

- LED frame for status display with illuminated presence detection

- Simple and intuitive operation

- Various smart home options (such as Loxone)

- Remote control from the living room (remote control 3200 and RGB 3200 Touch) or via Internet (froeling-connect.com)

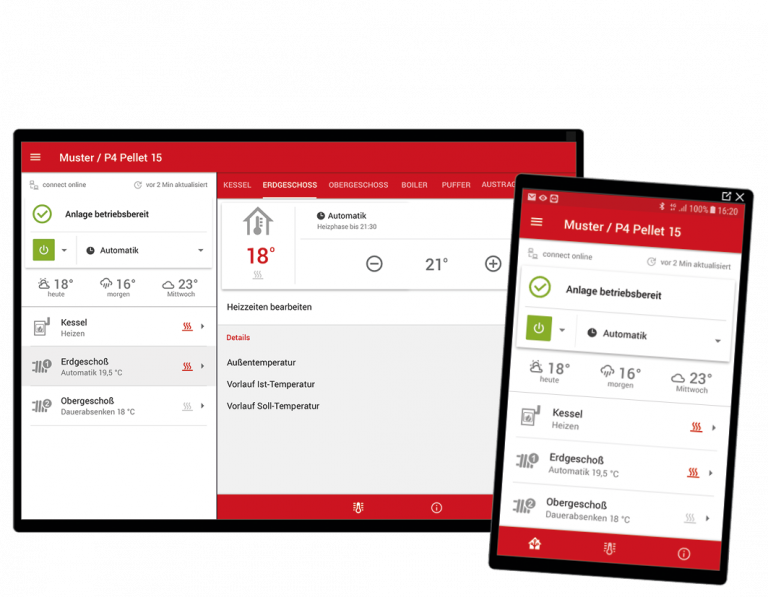

Keep track of everything with the Froling App

The Froling App allows you to check and control your Froling boiler online from

anywhere, at any time. You can read and modify the main status information and settings easily and conveniently online. You can also specify which status messages you want to be informed about via SMS or e-mail (e.g. when the ash box is to be emptied or in the event of a fault message).

The app is available in the Android Play Store and iOS App Store.

Advantages

- Simple and intuitive operation of the boiler

- Status information can be called up and changed within seconds

- Individual naming of the heating circuits

- Changes of status are notified directly to the user (e.g. via

e-mail or push notifications) - No additional hardware required (such as an Internet gateway)

Smart Home

Loxone

Combine your Froling heating system with the Loxone Miniserver and the new Froling Extension and implement individual boiler control on the basis of the single room control of the Loxone Smart Home.

Modbus

Via the Froling modbus interface, the system can be integrated

into a building management system.

Brochures / EU Label

Technical specifications

| Technical data - PE1 Pellet | 7 | 10 | 15 | 20 | 25 | 30 | 35 |

|---|---|---|---|---|---|---|---|

| Nominal output [kW] | 7 | 10 | 15 | 20 | 25 | 30 | 35 |

| Output range [kW] | 2 - 7 | 2 - 10 | 4,5 - 15 | 4,5 - 20 | 7,2 - 25 | 7,2 - 30 | 7,2 - 35 |

| Energy (ErP) label | A++ | A++ | A++ | A++ | A++ | A++ | A++ |

| Power connection [V/Hz/A] | 230V / 50Hz / abgesichert C16A | 230V / 50Hz / abgesichert C16A | 230V / 50Hz / abgesichert C16A | 230V / 50Hz / abgesichert C16A | 230V / 50Hz / abgesichert C16A | 230V / 50Hz / abgesichert C16A | 230V / 50Hz / abgesichert C16A |

| Weight [kg] | ca. 200 | ca. 200 | ca. 250 | ca. 250 | ca. 380 | ca. 380 | ca. 380 |

| Total boiler capacity (water) [l] | ca. 25 | ca. 25 | ca. 38 | ca. 38 | ca. 60 | ca. 60 | ca. 60 |

| Pellet container capacity [l] | 35 | 35 | 41 | 41 | 76 | 76 | 76 |

| Ashcan / ash box capacity [l] | 14,5 | 14,5 | 20 | 20 | 23 | 23 | 23 |

| Domestic hot water volume with optional DHW tank block [l] | 122 | 122 | 122 | 122 | - | - | - |

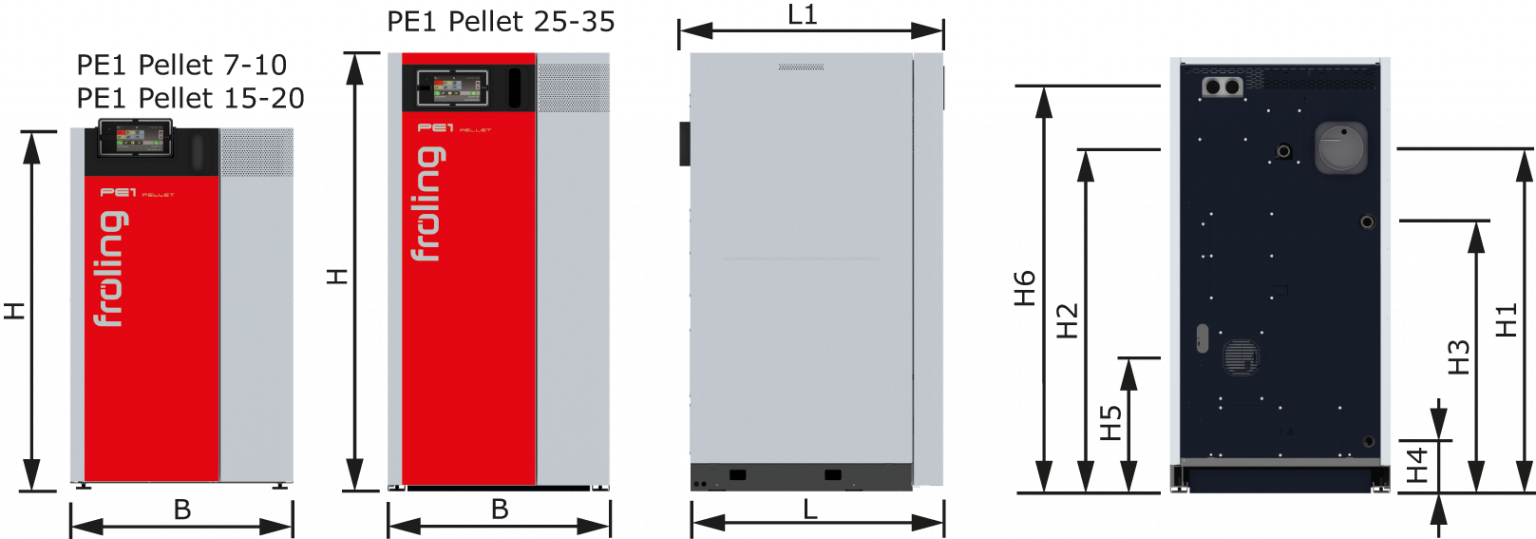

Dimensions

| Dimensions - PE1 Pellet [mm] | 7 - 10 | 15 - 20 | 25 - 35 |

|---|---|---|---|

| L Length of boiler | 690 | 690 | 850 |

| L1 Total length incl. flue pipe connection | 760 | 740 | 890 |

| B Width of boiler | 650 | 750 | 750 |

| H Height, boiler | 1240 | 1240 | 1480 |

| H1 Height, flue pipe connection | 940 | 940 | 1170 |

| H2 Height, flow connection | 930 | 930 | 1160 |

| H3 Height, return connection | 750 | 750 | 920 |

| H4 Height of drainage connection | 95 | 95 | 175 |

| H5 Height of supply air connection (for room air-independent operation) | 390 | 390 | 460 |

| H6 Height of suction system connection | 1110 | 1110 | 1380 |

| Flue pipe connection | 99¹ | 129 | 149¹ |

¹ Optional flue gas diameter of 129 mm without additional connecting adapter possible

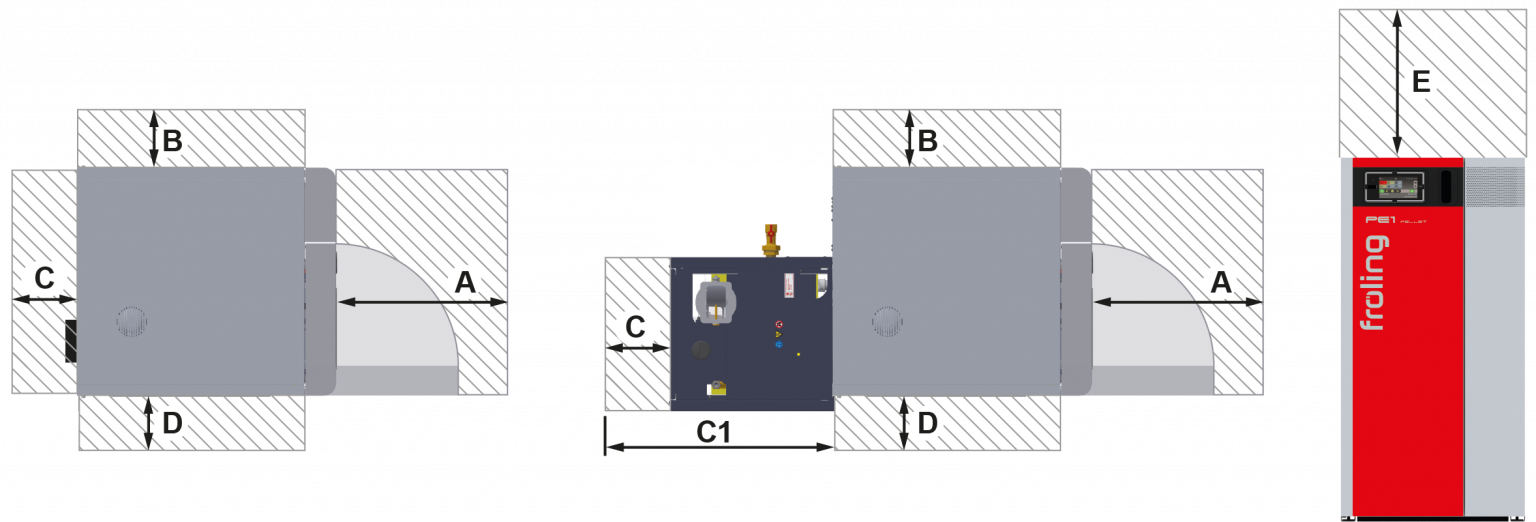

Operating and maintenance areas

| Minimum distances - PE1 Pellet [mm] | without DHW tank block and hydraulic block | with DHW tank block and hydraulic block |

|---|---|---|

| A Distance between insulated door and wall | 600 | 600 |

| B Distance between side of boiler and wall | 300 | 300 |

| C Distance between rear of boiler and wall | 300 | 30 |

| D Distance between side of boiler and wall | 100 | 100 |

| E Maintenance area above the boiler1 | 500 | 500 |

¹ Maintenance area to expand the WOS springs upwards

Technical documentation

For you personally

Information & advice

You would like to have further product information or you have general questions regarding our company?