FIREWOOD BOILER

20 – 45 kW

Available with broad-

band lambda probe

and servo-motors

Firewood boiler

Top-quality boiler technology at a mid-range price

The S3 Turbo firewood boiler focuses on the basics. It includes many features that you would normally only find in high-end firewood boilers.

- Patented, cylindrical high-temperature turbulence

combustion chamber for excellent combustion values - Separate pre-heating chamber door for easy pre-heating

- Carbonisation gas extraction system for smoke-free reloading

- Speed-regulated induced draught fan for output control and

full operating safety.

Information/advice

You would like to have further product information or you have general questions regarding our company?

The latest technology

Speed-regulated induced draught fan

Large fuel loading chamber for logs up to 56 cm in length

WOS system Efficiency Optimisation System

Top quality insulation to minimise radiant heat loss

Actuators for primary and secondary air (or actuators with Lambdatronic)

Actuators for primary and secondary air (or actuators with Lambdatronic)

Large maintenance openings for easy cleaning

S-Tronic PLUS controller or Lambdatronic controller

Carbonisation gas extraction system prevents smoke escaping during reloading

Cladding to protect the inner wall of the boiler and for a longer service life

Separate ignition door for easy start up

Patented high-temperature turbulence combustion chamber ensures low emissions

System convenience

S-Tronic PLUS control

- Speed regulation and function monitoring of the induced draught fan for output adjustment

- Integrated storage tank management

- Visual display with control keys for setting

- Can be used to control 2 mixed heating circuits

- Integrated boiler management

Lambdatronic control

- Speed regulation and function monitoring of the induced draught fan for output adjustment

- Lambda control with broadband lambda probe

- Control of primary and secondary air via 2 servo-motors

- Integrated storage tank management

- Visual display with control keys for setting

- Can be used to control 2 mixed heating circuits

- Integrated boiler management

Brochures / EU Label

Technical specifications

| Technical specifications - S3 Turbo | 20 | 30 | 40 | 45 | |

|---|---|---|---|---|---|

| Nominal output | [kW] | 20 | 30 | 40 | 45 |

| Energy (ErP) label | Composite label (boiler + controls) | A+ | A+ | A+ | A+ |

| Fuel loading chamber capacity | [l] | 140 | 140 | 210 | 210 |

| Fuel loading door (width/height) | [mm] | 330 / 370 | 330 / 370 | 330 / 370 | 330 / 370 |

| Water capacity | [l] | 120 | 120 | 190 | 190 |

| Boiler weight | [kg] | 525 | 535 | 610 | 620 |

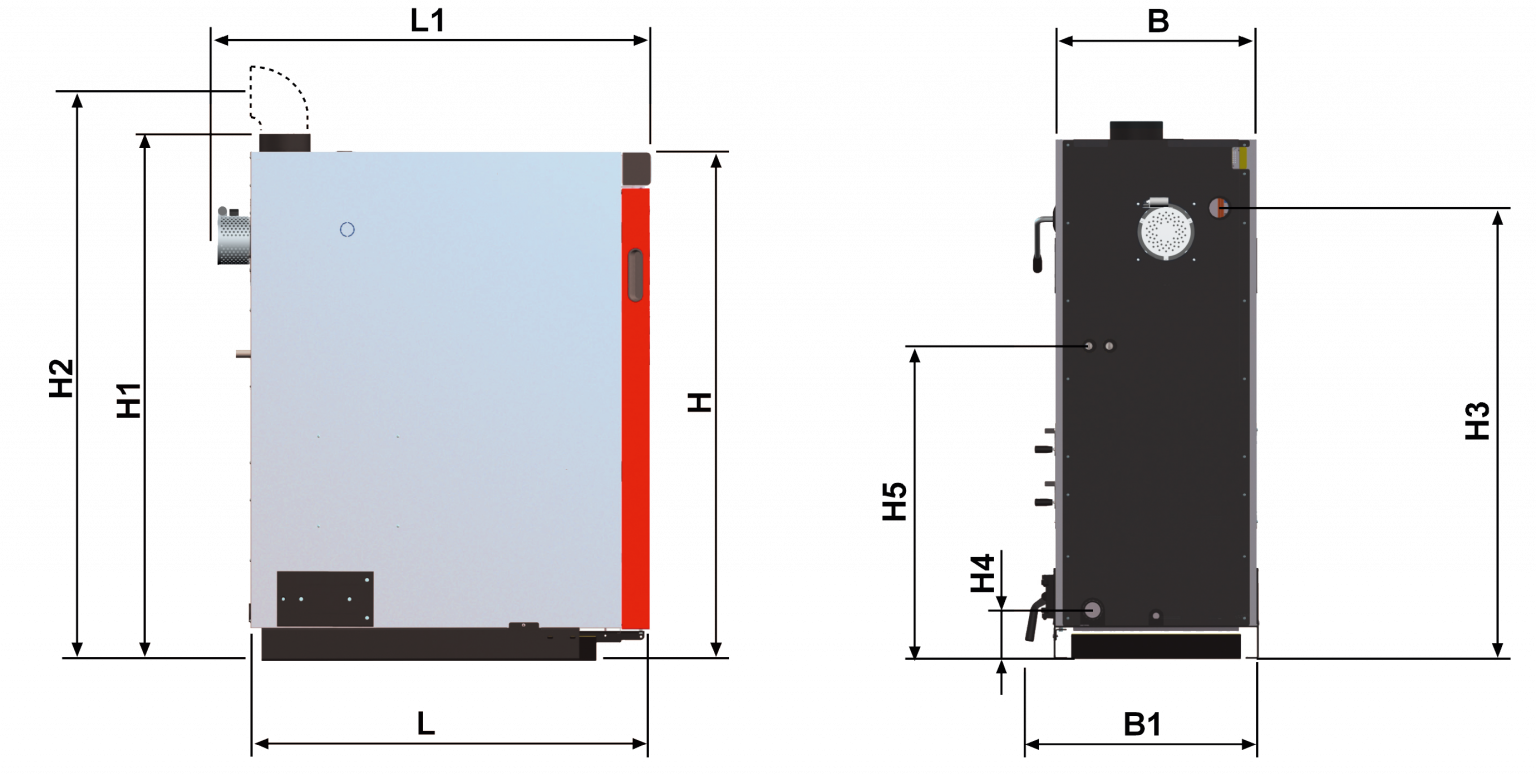

Dimensions

| Dimensions - S3 Turbo [mm] | 20 | 30 | 40 | 45 |

|---|---|---|---|---|

| L Length of boiler | 1160 | 1160 | 1250 | 1250 |

| L1 Total length including induced draught fan | 1260 | 1260 | 1350 | 1350 |

| B Width of boiler | 570 | 570 | 670 | 670 |

| B1 Total width including side cleaning door | 680 | 680 | 780 | 780 |

| H Height of boiler | 1470 | 1470 | 1570 | 1570 |

| H1 Total height including flue gas pipe | 1530 | 1530 | 1630 | 1630 |

| H2 Height of flue pipe connection | 1635 | 1635 | 1735 | 1735 |

| H3 Flow connection | 1280 | 1280 | 1380 | 1380 |

| H4 Return connection | 140 | 140 | 140 | 140 |

| H5 Safety heat exchanger connection | 890 | 890 | 970 | 970 |

| Flue pipe diameter | 149 | 149 | 149 | 149 |

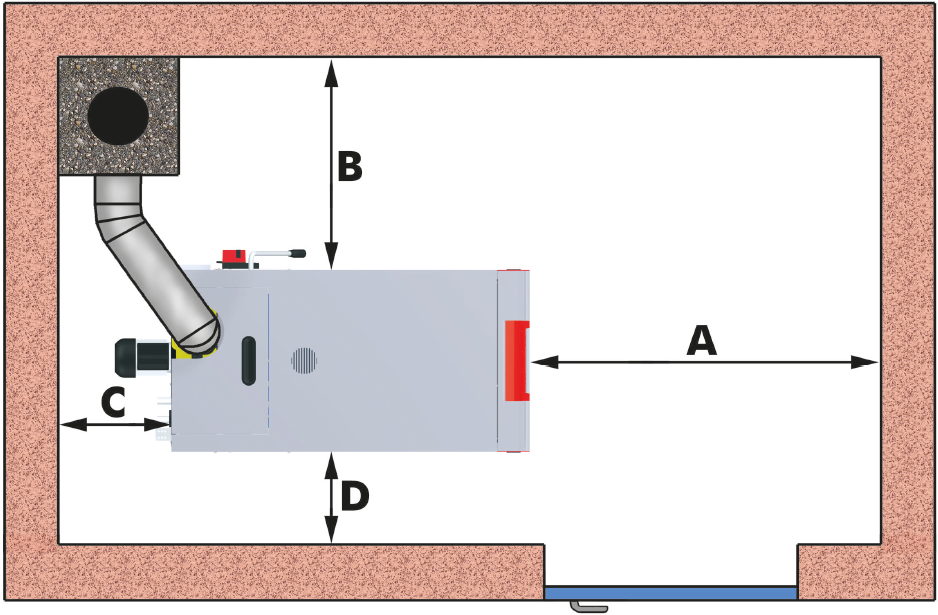

Operating and maintenance areas

| Minimum distances - S3 Turbo [mm] | 20-45 |

|---|---|

| A Distance - front of boiler to wall | 800 |

| B Distance – side of boiler to wall | 800 (200)¹ |

| C Distance – back to wall | 500 |

| D Distance – side of boiler to wall | 200 (800)¹ |

¹ The side of the boiler where the WOS lever is located (B or D) should be at least 800 mm from the wall to allow easy access for connecting the appliance and for

maintenance work (e.g. induced draught).

Technical documentation

For you personally

Information & advice

You would like to have further product information or you have general questions regarding our company?